Navigating Business Development in Oil & Gas: The Digital Thread Advantage

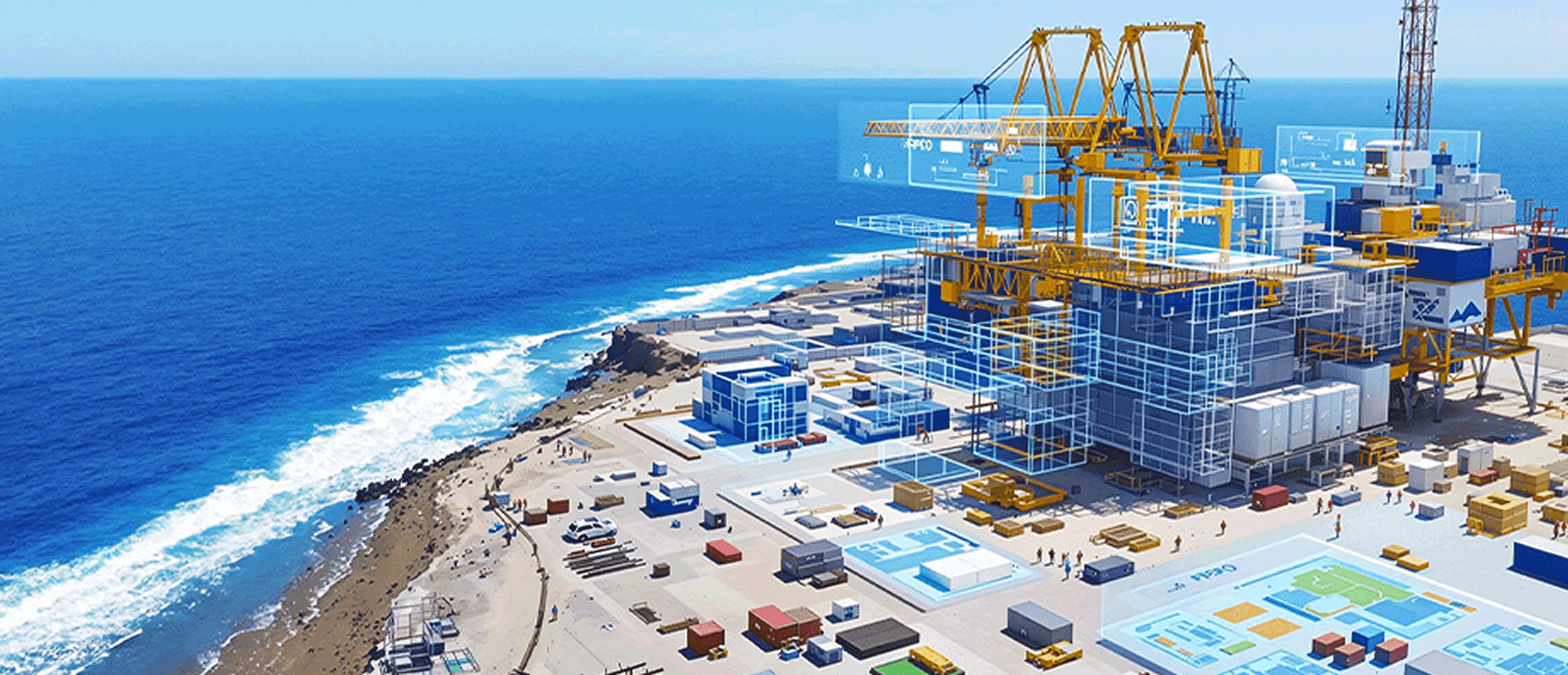

In the competitive landscape of the oil and gas industry, business development is pivotal. The advent of Digital Thread technology has opened new avenues for project planning, execution, and monitoring, becoming a cornerstone for business development initiatives in the sector.

The Digital Thread Edge

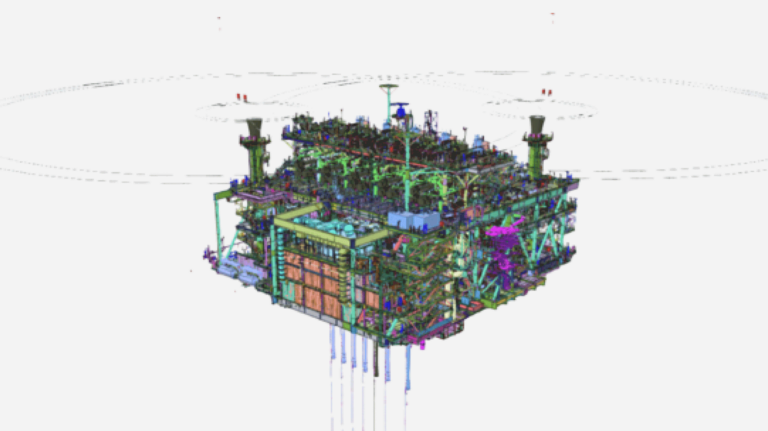

Digital Thread technology creates a virtual replica of physical assets, processes, and systems. In the oil and gas sector.

Market Growth Drivers

Enhanced Planning

With accurate simulations, companies can plan projects meticulously, considering various scenarios and their potential outcomes.

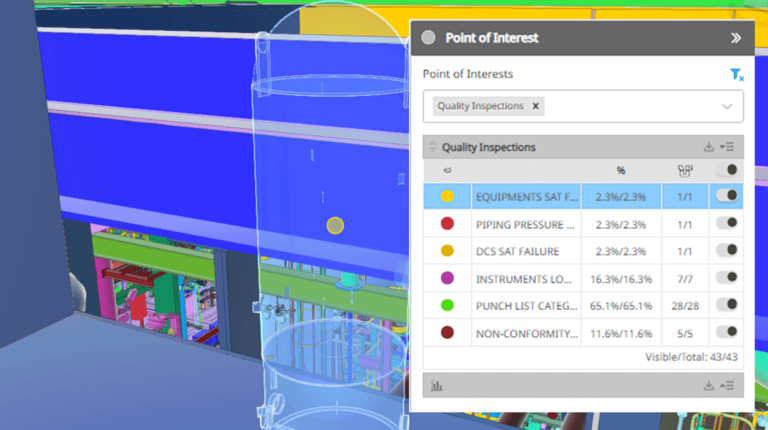

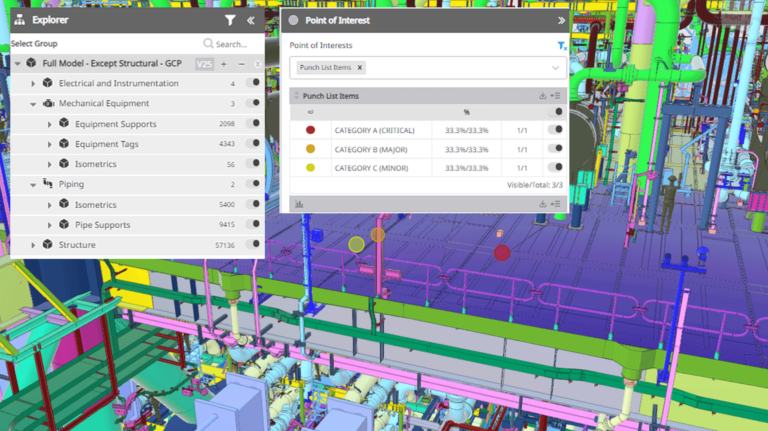

Real-time Monitoring

Digital Threads allow for continuous monitoring and analysis of operations, providing insights that are crucial for timely decision-making.

Risk Management

The technology aids in identifying and mitigating risks early, ensuring that projects are executed smoothly and efficiently.

Business Development Implications

Strategic Planning

Digital Threads facilitate strategic planning by providing a holistic view of assets and operations, allowing companies to identify opportunities for expansion and investment.

Client Engagement

With the ability to showcase virtual replicas of projects, companies can engage clients and stakeholders effectively, enhancing communication and collaboration.

Case in Point: Konnect xD

At Konnect xD, we understand the intricacies of business development in the oil and gas sector. Our Digital Thread platform is designed to empower companies to plan, monitor, and analyze projects seamlessly, providing a competitive edge in business development endeavors.

Conclusion

In the realm of business development within the oil and gas industry, Digital Thread technology is not just an asset; it’s a necessity. It provides the tools and insights required for strategic planning, client engagement, and market positioning, driving business growth and success.

Get in touch with us

Embark on a transformative journey with Konnect xD’s Digital Thread platform, designed to navigate the complexities of business development in the oil and gas sector. Explore our solutions and unlock the potential of digital innovation for your projects!

Frequently Asked Questions

-

Improved Collaboration: Connects teams across departments and geographies, ensuring everyone works with the same data.

-

Improved Efficiency: Reduces errors and rework by automating data flow between systems.

-

Improved Product Quality: Tracks changes and root causes of issues throughout the product lifecycle. Continuous feedback loops ensures that product improvements are informed by real-world performance.

-

End-to-End Visibility: Breaks down silos, providing stakeholders with real-time insights across departments.

-

Enhanced Traceability: Tracks the evolution of a product throughout its lifecycle, making it easier to identify and correct issues.

-

Faster Time to Market: Streamlined workflows reduce delays and bottlenecks, enabling quicker product development.

-

Cost Savings: Minimized errors and rework lead to reduced costs in design, production, and maintenance.

-

Better Decision-Making: Real-time access to data supports data-driven decisions and predictive analytics.

-

Faster Decision-Making: Enables data-driven decisions with up-to-date, contextualized information.

-

Regulatory Compliance: Simplifies adherence to industry standards and regulations by maintaining a complete record of the product lifecycle.

| Aspect | Digital Thread | Digital Twin |

|---|---|---|

| Definition | A unified framework that connects data across the product lifecycle. | A virtual replica of a physical product, process, or system that mirrors real-world conditions in real time. |

| Scope | Focuses on the flow of information across systems and stages. | Focuses on the simulation and monitoring of a specific product or system. |

| Purpose | Ensures traceability, collaboration, and data consistency from design to end-of-life. | Provides insights into performance, predicts failures, and tests scenarios in a virtual environment. |

| Data Flow | Linear and continuous, linking all lifecycle stages. | Bi-directional, with real-time feedback between the physical and virtual representations. |

| Use Cases | Lifecycle management, compliance, and end-to-end traceability. | Real-time monitoring, predictive maintenance, and performance optimization. |