Category: Newsroom

USPI x Twintech Partnership (FL3DMS)

Twintech Partners with USPI to Augment the Future of 3D Modeling Standards

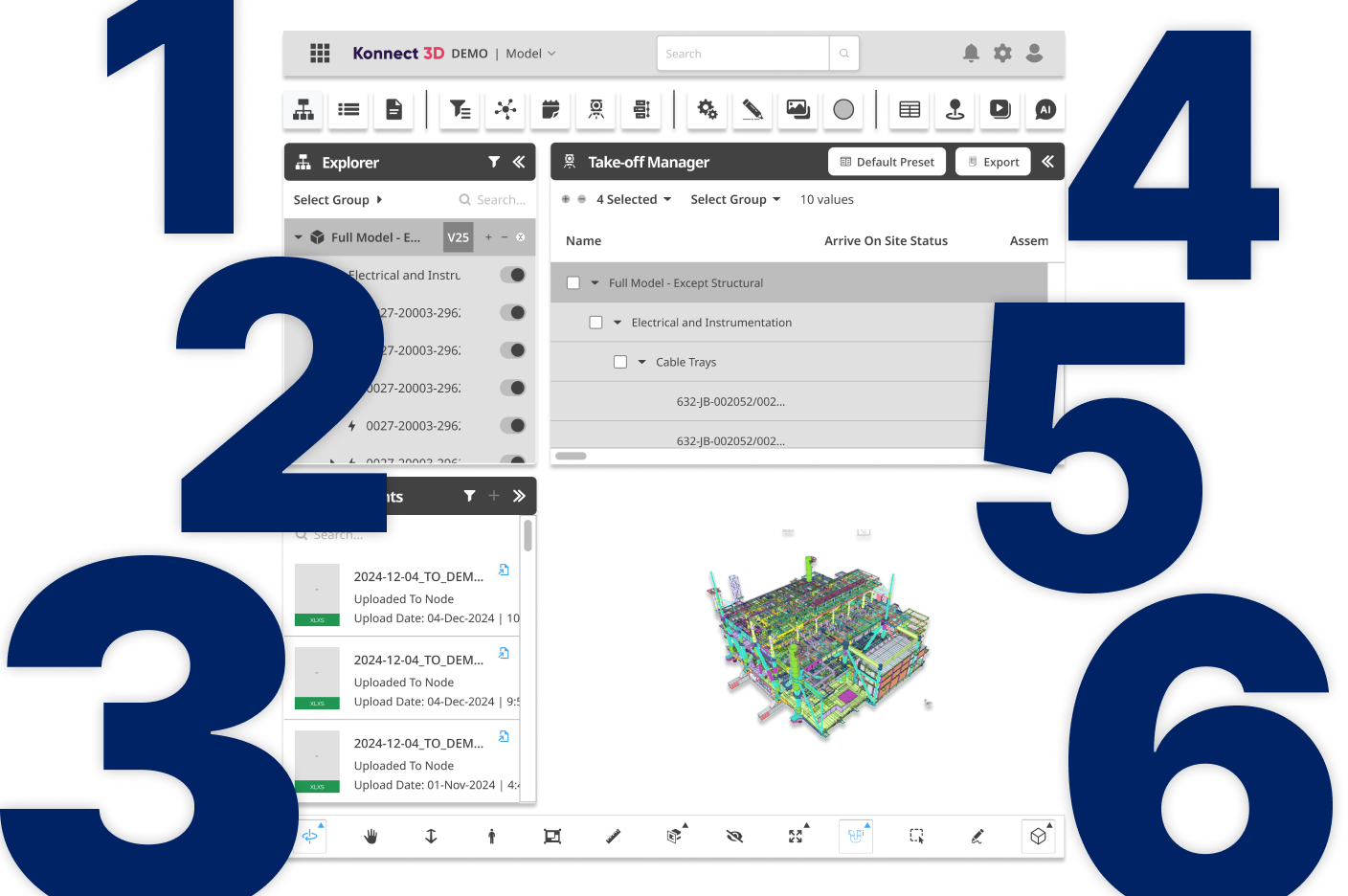

Sequencing Success

FPSO Almirante Tamandaré Leverages Konnect xD for Strategic Material Allocation

SBM OFFSHORE and FPSO Sepetiba

Unlocking the Potential: Three Effective Strategies for Harnessing Data to Drive Predictability in Construction